What you’ll learn

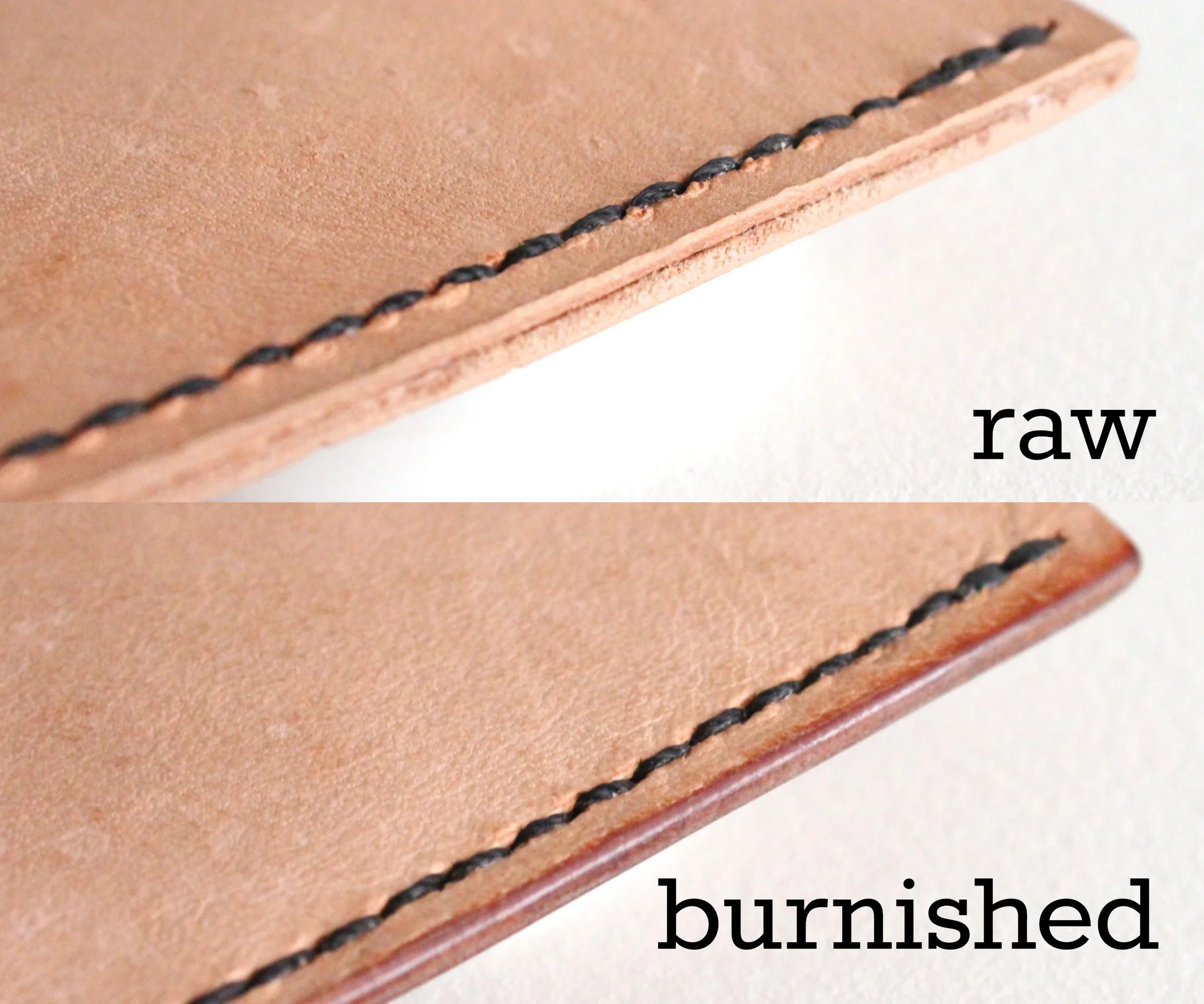

This tutorial shows a reliable, repeatable method to turn fuzzy edges into durable, smooth ones. You’ll prepare the edge, burnish with friction, then optionally color and seal for a long-lasting finish.

Tools & materials

- Edge beveler (size matched to leather thickness)

- Sandpaper 400→800 (or sanding sticks)

- Water or gum tragacanth / Tokonole

- Wood or bone burnisher (hand or drill-mounted)

- Cloth scrap or canvas for final polish

- Optional: edge dye, edge paint, beeswax/paraffin, heat creaser

Prep & setup

- Use veg-tan for classic glassy edges; many chrome-tans still improve with burnishing.

- Finish all cutting and punching before working edges.

- Protect your work surface; keep a damp sponge nearby.

Step-by-step

Bevel the edge

Run the beveler lightly on both sides to soften corners. Keep the tool upright and steady for a consistent round-over.

Sand smooth

Sand the edge with 400→800 grit using small, even strokes. You’re removing tooling marks and evening layers.

Dampen the edge

Lightly wet the edge with water or apply gum/Tokonole. It should feel slightly tacky, not soaked.

Burnish

Rub briskly with a wooden/bone burnisher until the edge darkens and shines. Add a touch more moisture if it squeaks.

Optional color

Apply edge dye or paint in thin coats. Let dry between passes. Lightly sand any ridges before the next coat.

Seal & polish

Rub a tiny amount of wax along the edge and burnish again. Final buff with cloth or canvas for a glassy finish.

Tips

- Short, repeated burnish passes beat one long aggressive pass.

- If the edge feels fuzzy again after drying, lightly sand and do one more quick burnish.

- Match beveler size to leather weight for nice, even domes.

Troubleshooting

- Matte, dull edge: Not enough friction or moisture—add a touch of water/gum and burnish longer.

- Edge gets mushy: Too wet—let it dry a minute, then burnish again.

- Uneven dome: Bevel both sides consistently; re-sand lightly and reburnish.